Manufacturing in Ireland. Reinventing a Company

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

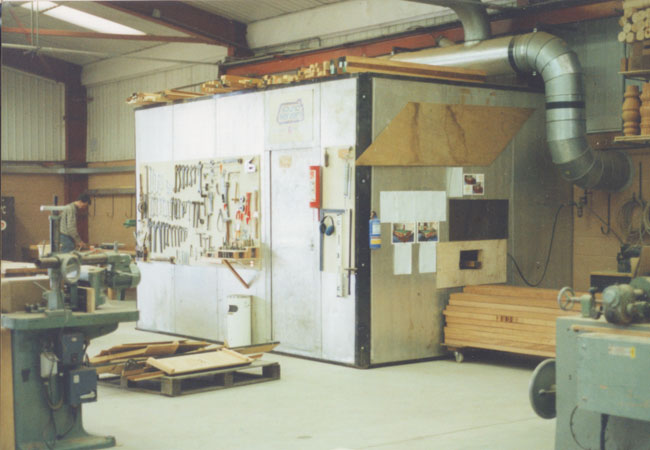

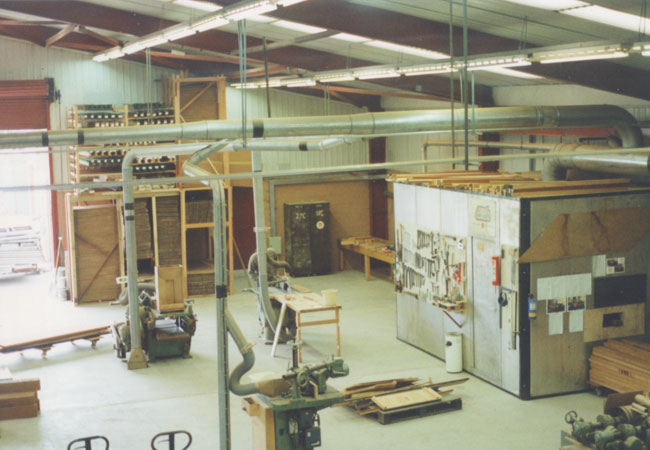

So we were up and running again.

We were tight for space but the layout was better than in Burnley.

We had compensated for the lack of space by purchasing 4 of the 40 ft sea containers that brought the factory and installing 2 of these for storage at the back of the factory and 2 at the side to house the sawdust extraction unit. Finer dust from sanding was handled by a separate unit also placed outside.

The reader will note from the photos that much of the machinery was dated to say the least.

Indeed a number of tools dated from the Rosegrove factory and had originally been belt driven from a steam engine.

The equipment was functional, robust and up to the task but if we were to compete with the likes of Riley or BCE we would need to retool.

IDA were now the major headache. They had a problem in that the funds used in the takeover and the move to Ireland were from deposits and sales and were thus not technically capital. They were fully informed as to how we were financing the deal, and the capital implications of the way the deal was structured, before we moved.

Again they only told us they had a problem with all this when we were in Ireland. Is all of this was carefully designed to give the impression that IDA were giving us something when in fact their relationship with the project was parasitic?

So they set up a mechanism called a “subordinated loan.” This was a loan from ourselves to the company. This subordinated loan of 30k punts was made up of other funds we had already contributed to the takeover. The agreement was dated 3rd June 1992 and was for a period of 3 years. All of this was expensive to set up as was the company structure set up on IDA/KPMG advice (an Irish branch of an IOM company).

Our first accountancy period was closed at 18 months and the company had made a small profit.

Considering that we had moved the factory from one country to another, trained new staff and so on we considered this to be a very good performance. I had however been forced to manage the factory myself to achieve this performance. Productivity in terms of man hours per table was also a marked improvement over what had been achieved in the UK.

All of this did take a toll on us as a family. We had 4 young children in school at home in Belgium and so the project was taking a heavy toll on us. We were committed however and planned to move the kids to Ireland as soon as possible.

We were now selling directly from Ireland to our agents so our Belgian company had lost the agent's commission it had enjoyed when the factory was in England. Our lucrative Belgian table rental business was also dwindling away due to lack of attention. As a family we were putting a lot of eggs in one Irish basket.

We also took no wages in Ireland. We needed new machinery and felt we should keep all monies for this. However we then got a visit from the Inland Revenue who informed us that we would have to pay income tax on our expenses while in Ireland and so we were forced to pay 15k back tax on the all the expenses we incurred since the factory came to Ireland and we now had to join the Irish PAYE system. The Revenue were fully aware that we were paying income tax and social security in Belgium and that our household had no benefit from Ireland but this made no difference. This 15k cost the project a badly needed new machine.

1993: The Snooker Market Contracts

In 1993 the market for the snooker tables on the Continent began to contract. There was a major bankruptcy of a large chain of snooker clubs in the Netherlands which frightened the market while at the same time releasing a large quantity of second hand tables onto the market at liquation prices. We were faced again with some big decisions. We discussed our situation with the IDA and with our agents. Our main agents Gauselmann offered to give us their American Pool table order which was very big and which they normally sourced in the US.

An American table is a very different animal. As I had indicated in our original proposal to IDA Amsterdam we had always intended to get into pool and we have been developing a table since our arrival in Ireland. On the continent clubs are often multi disciplined and have a mix of Snooker, Pool and Carom (classic Continental Billiards.) So we had been working to develop both a Pool table and a Carom table.

These tables were designed in fact to help sell snooker tables as club owners often needed all 3 disciplines in the same style.

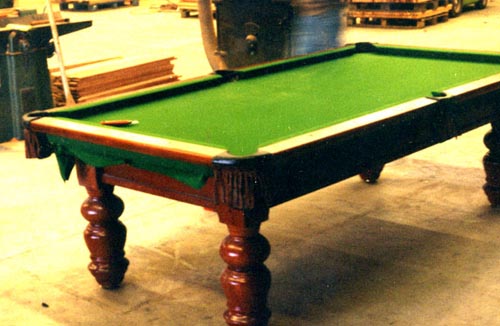

1993-01-27 Frankfurt. First attempt at Pool |

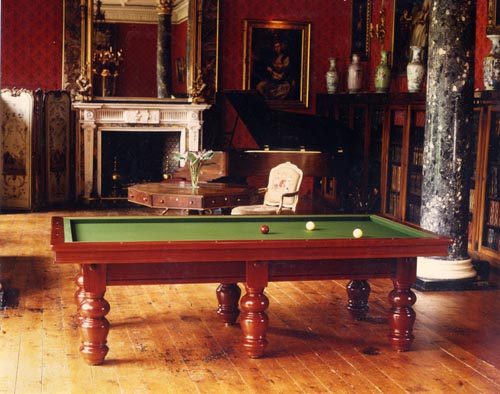

Carom Table Bantry House. |

The Carom table was satisfactory and fit for purpose as Carom tables command a relatively high price. This first attempt at a Pool table however was a beast involving way too many man hours and was very heavy on materials. Pool tables do not command such a high price. If we were to compete with the Americans on price we would need to do a great deal better with our design. We would need a very different table. We knew this would be a difficult thing to pull off. IDA were supportive and gave assurances that the factory would be sold to us later as originally agreed. We were reassured that the conditions were, as we were told in the beginning, that we have a healthy order book and good profitability. This effort would also entail sacrifice from us as a family but we felt a sense of loyalty to the project and the team we now had in Clonakilty.

So we started rapid development of our new products. There was no time for product testing and any problems or retrofitting required was carried out on the ground by Euromart (now renamed Willie Holt Belgium BVBA) free of charge.

|

|

|

Trying to save on materials we tried a second table with a mitered pocket but soon found that we could not consistently achieve the required accuracy with the equipment we had. We would need a CNC capacity to pull this system off. So we reluctantly went for a leather and metal pocket. Initially the table had 6 legs but we later changed to 4 legs with a metal undercarriage again in an attempt to cut costs. We also went for pre-manufactured veneered MDF for the frame rather than timber in order to cut the ratio of man hours per table.

This first “snooker type” table we called the Carbery Pool and it was a market success but had still insufficient margin per man hour. We were now making lots of tables but losing money.

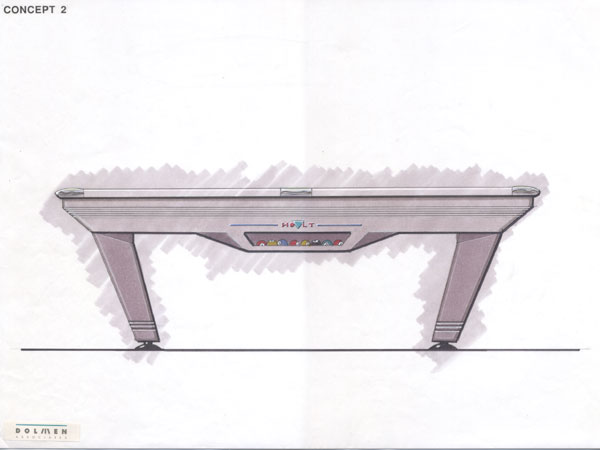

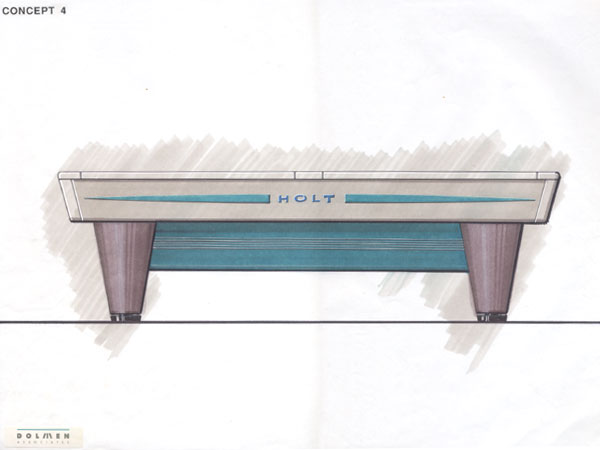

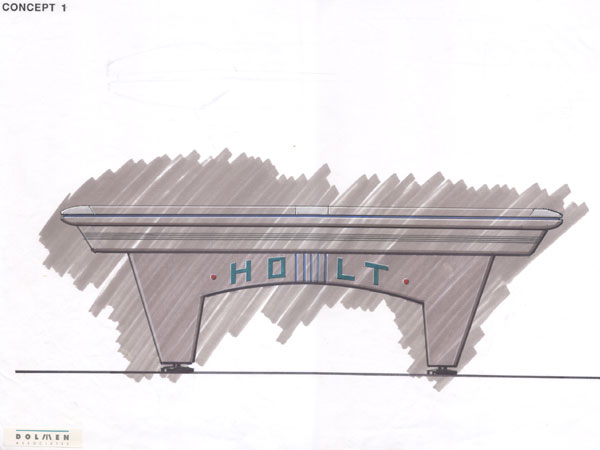

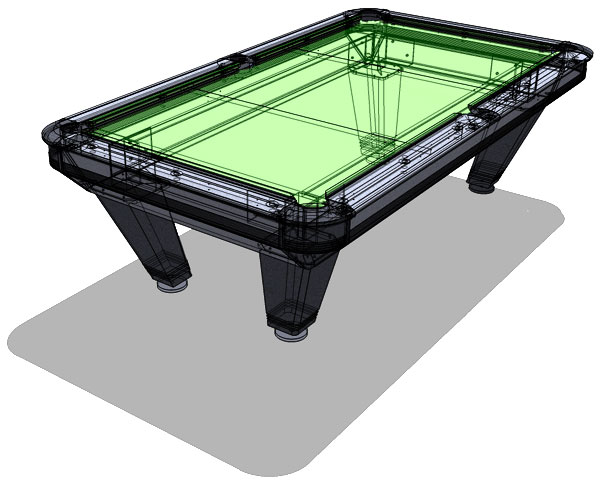

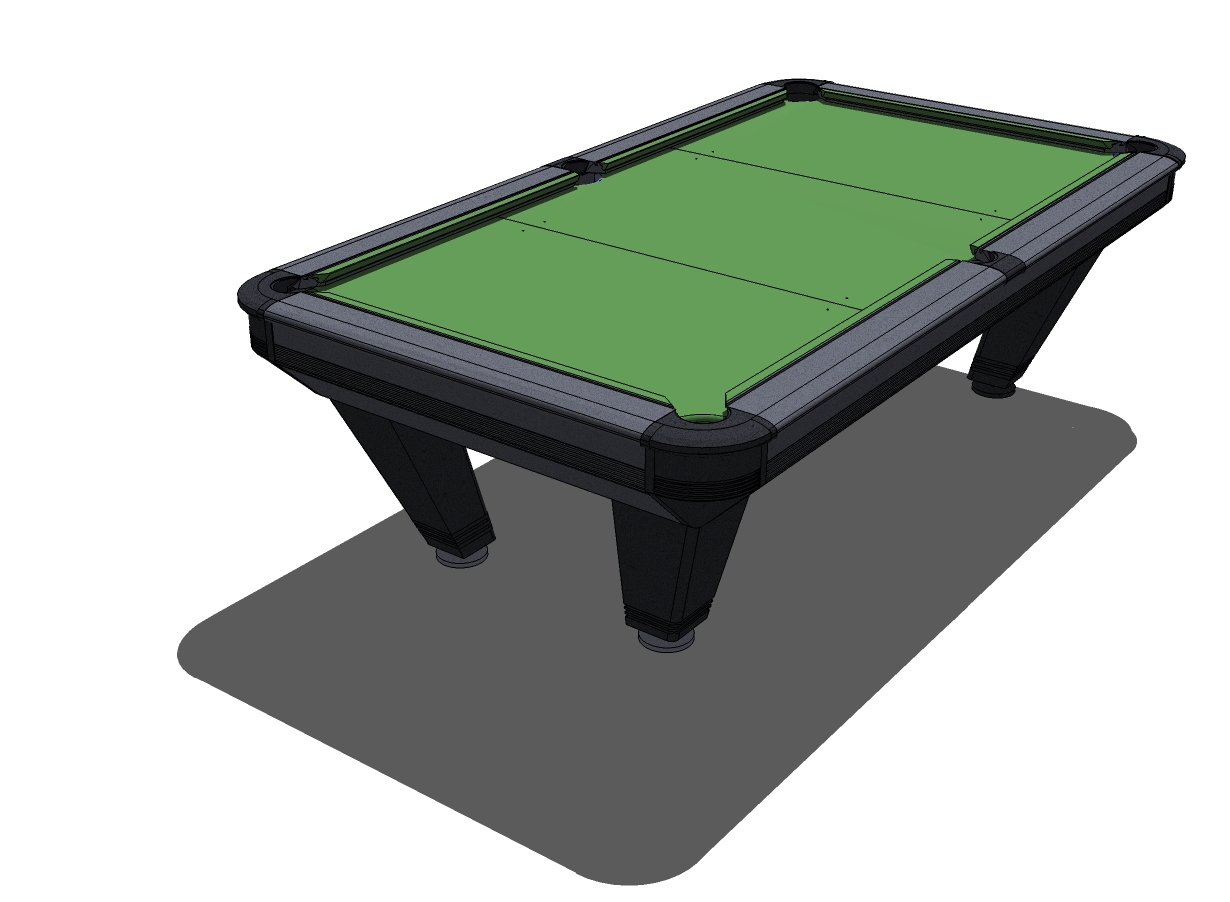

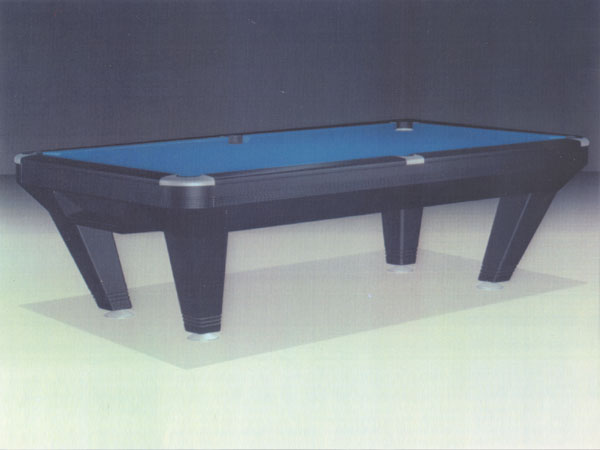

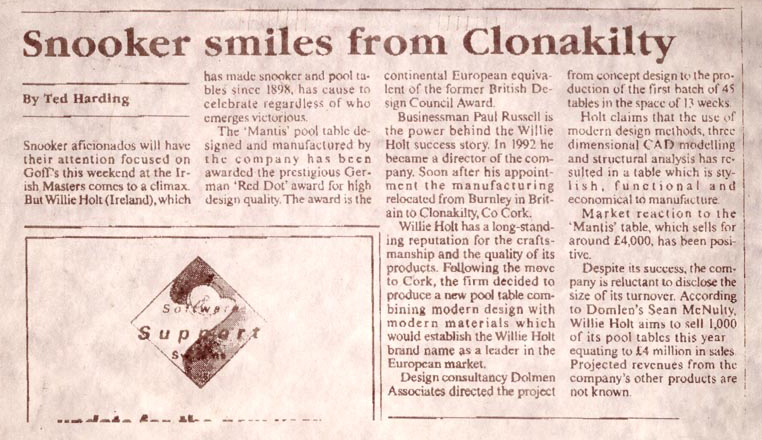

So we decided on a much more radical approach. We employed the services of the professional industrial design team at Dolmen Associates in Dublin and they produced some concept drawings.

|

|

|

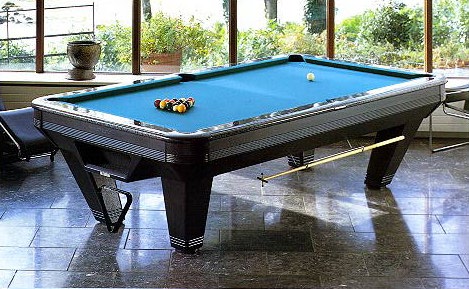

We selected the one on the right and christened it the “Mantis”. This was about as radical a departure as you could imagine. We were now faced with the job of fleshing out the design and fitting a billiard table into it, a not inconsiderable task.

|

|

|

|

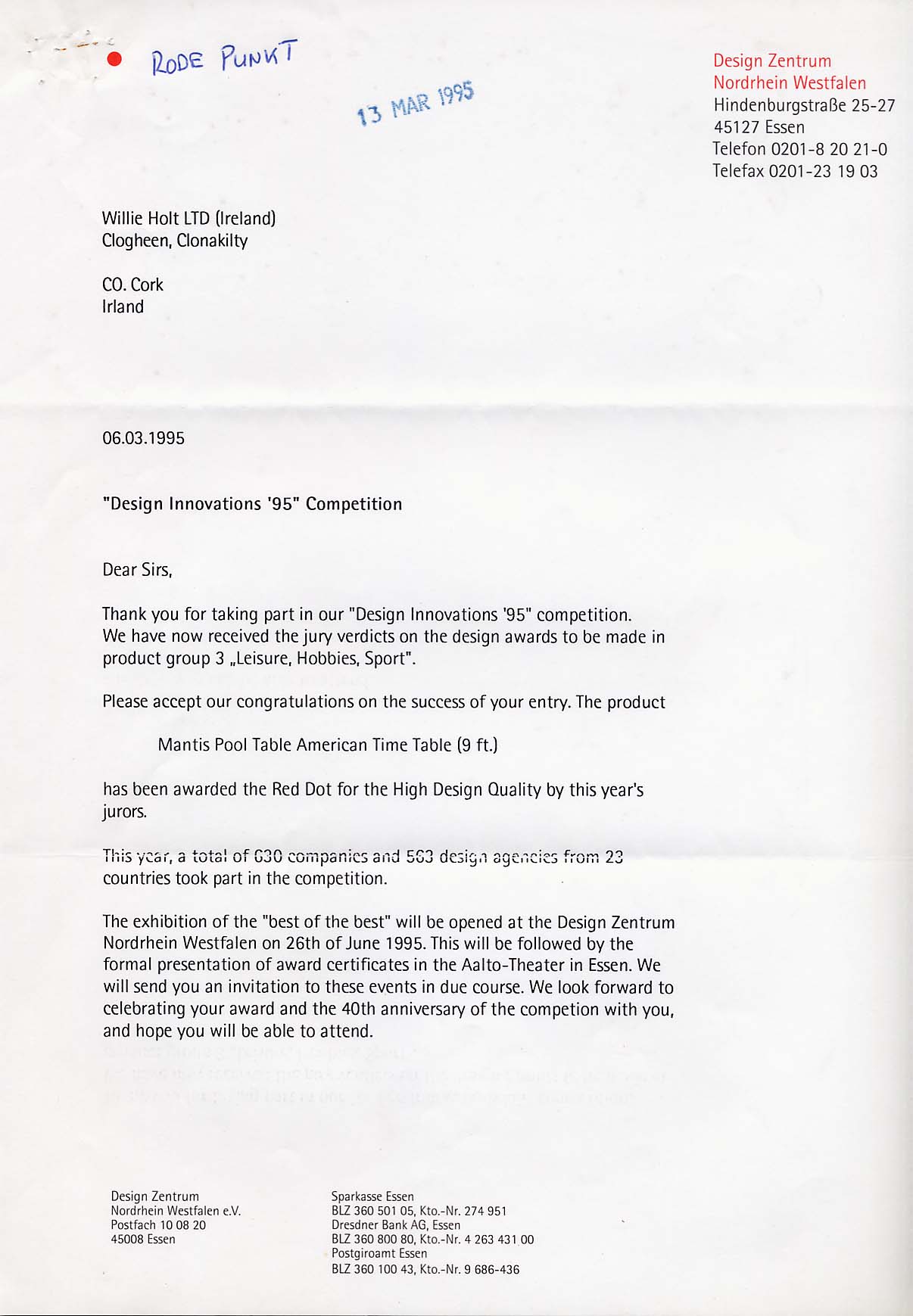

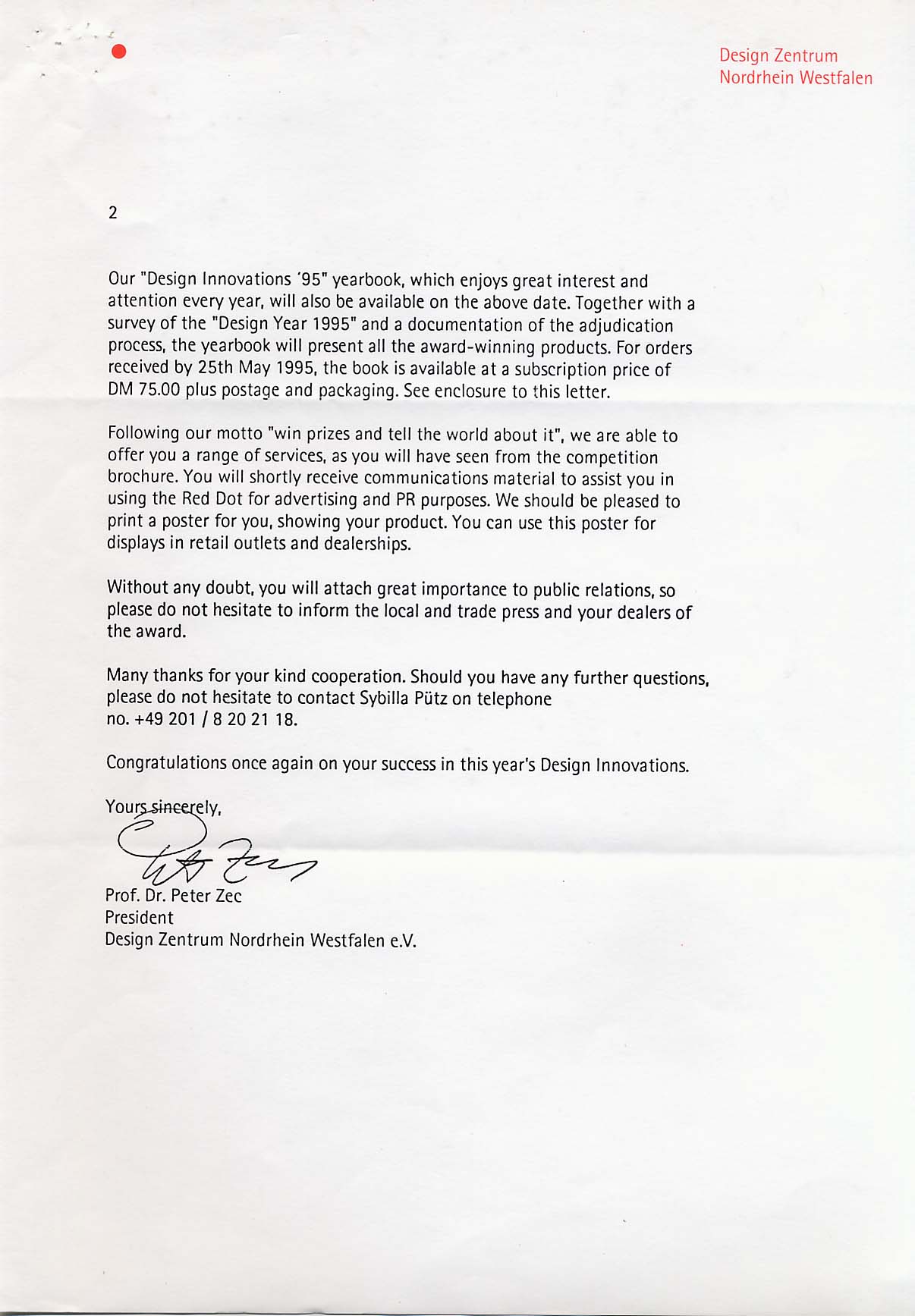

This table was a big success and was awarded the “Red Dot” award which is the German equivalent of a British Design Council Award.

|

Red Dot |

Red Dot |

Red Dot |

||

So after a year of very hard work and substantial losses we were now back in profitability and our order book was again equivalent to our capacity with a new and profitable product. We carried the losses during this transition by extending our overdraft facility with AIB under a personal guarantee and by Gauselmann going over to prepayment on each container of tables.

For the first time since our arrival in Ireland we were now secure. Profitability was running at 10% of turnover and turnover was made up of 93% of new products which had never been made in the UK.

We invested in new equipment and a new catalogue reflecting our new range. We also invested in a new more up to date corporate image.

We also decided to invest in new markets to move away from our reliance on Gauselmann.

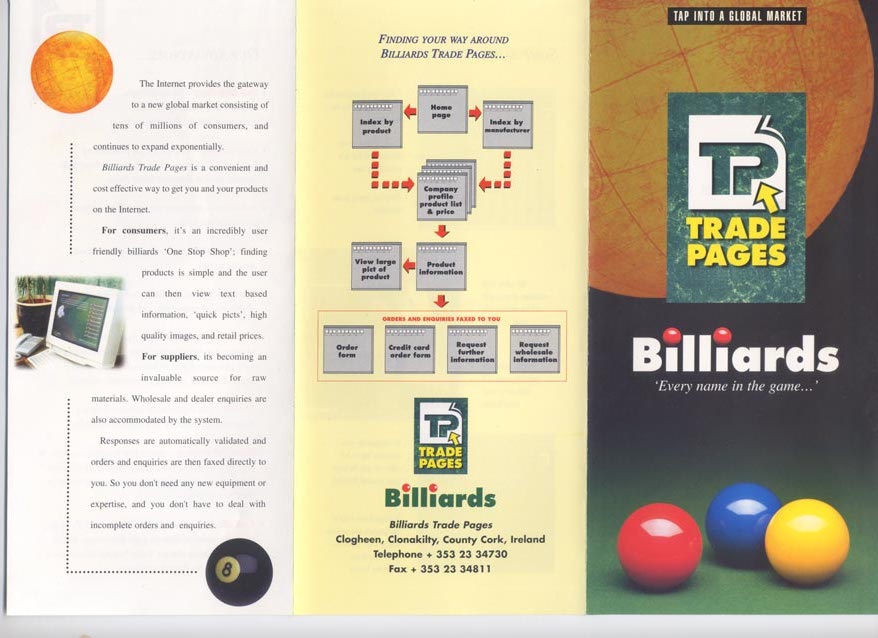

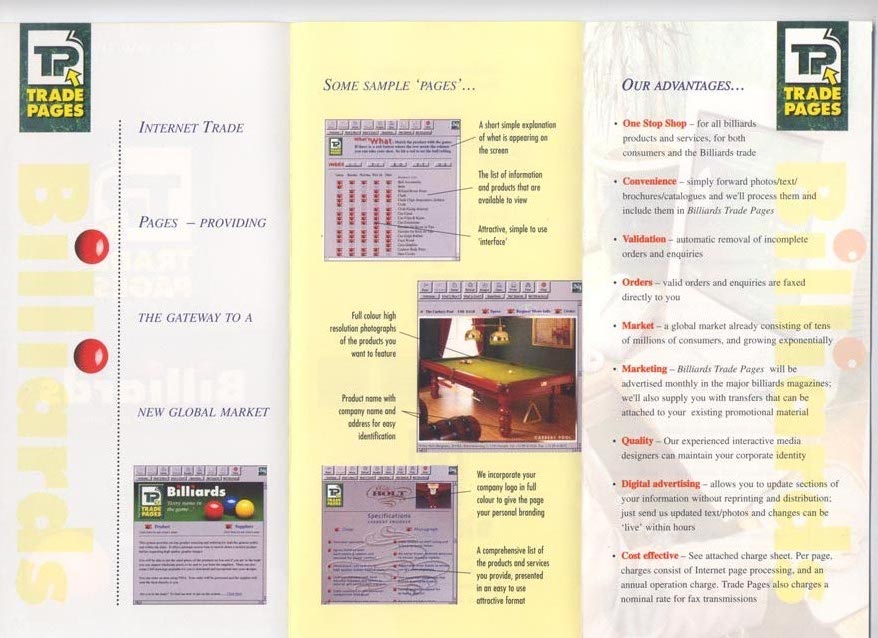

So we invested in the US and we invested in a new data based ecommerce system (in UNIX/PERL/Msql) which would allow us to market worldwide.

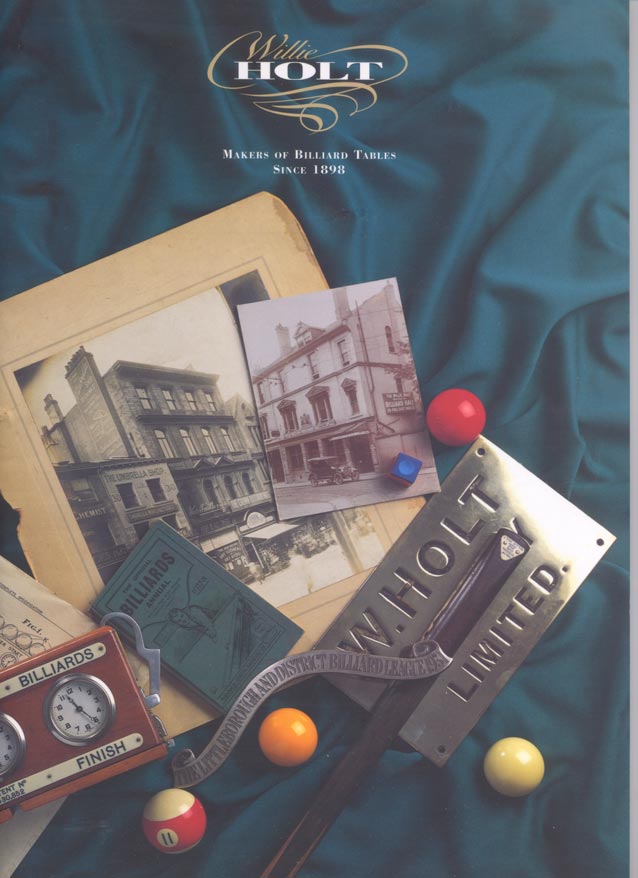

New Catalog |

New Logo |

Ecommerce System 1 |

Ecommerce System 2 |

Billiards Trade Fair Prague |

We decided to do the ecommerce system as a subsidiary of Holts as we felt the ecommerce scripts we had developed would work for other companies and would need further investment in the future. We now committed our last reserves and invested a further 60k into Ireland. This was added to 30k from Holts bringing the ecommerce investment to 90k. We first employed a Software company from Kerry to develop the system we wanted but this was an expensive failure. We were then very lucky to find Ireland’s foremost expert in the field Mr. Peter Flynn from UCC who became the project consultant.

Scripting was done initially by FMA in Edinburgh who were webmasters for the UK ISP Demon. Later we did the programming in-house. This system was, as far as we are aware today, the most advanced ecommerce system developed in Ireland at that time. For more details on the Trade Pages project please click here.

On the family side we planned to relocate our children to Ireland in the summer and we were in the process of building a house in Clonakilty.

We had had a Forbairt Technology Audit which had concluded:

For The Full Text of the Audit Click Here |

So we were confident of our relationship with the Irish State agencies by now and had put the dirty tricks played on us when we arrived in Ireland behind us.

Was this confidence somewhat premature? Was the dirty tricks department was alive and well?

Please take the time to answer our Poll on the right hand side of this page and if you have any comments use the “comments” link at the bottom of this page.